When we ask if stainless steel is a homogeneous mixture, we’re wondering if it’s made the same way all through. Imagine mixing chocolate syrup in milk until you can’t see any syrupy spots – that’s like stainless steel, where everything is mixed so well, it looks and acts the same everywhere.

Have you ever mixed different colors of playdough and couldn’t see the separate colors anymore? That’s what we think about when asking, is stainless steel a homogeneous mixture? It’s like the playdough – mixed so well, the special ingredients make it strong and shiny everywhere.

Asking is stainless steel a homogeneous mixture? is like wondering if your smoothie is the same from top to bottom. Stainless steel is mixed so everything – like its strength and shine – is the same all over, making it super good for things like spoons and bikes.

Understanding Stainless Steel

Before we can completely cope with whether or not chrome steel is a homogeneous mixture, it is vital to apprehend what stainless-steel is. Stainless metal is an alloy, because of this it’s made through combining or more metallic elements to create a cloth with more advantageous houses.

The number one issue is iron, to which chromium (as a minimum 10.Five%) is brought to gain corrosion resistance. Other factors like nickel, molybdenum, and titanium can also be blanketed to regulate the alloy’s traits. how to passivate stainless steel?

The Homogeneity of Stainless Steel

Stainless metallic, determined at a larger, macroscopic scale, showcases a constant or even composition, leading to its type as a homogeneous aggregate for sensible functions. This uniformity plays an important function in its big programs throughout diverse industries.

The regular nature of stainless-steel ensures that its important properties, including durability and the ability to withstand corrosion, continue to be uniform across any piece of stainless steel. Such consistency is imperative, mainly in contexts in which the fabric’s power and toughness are important.

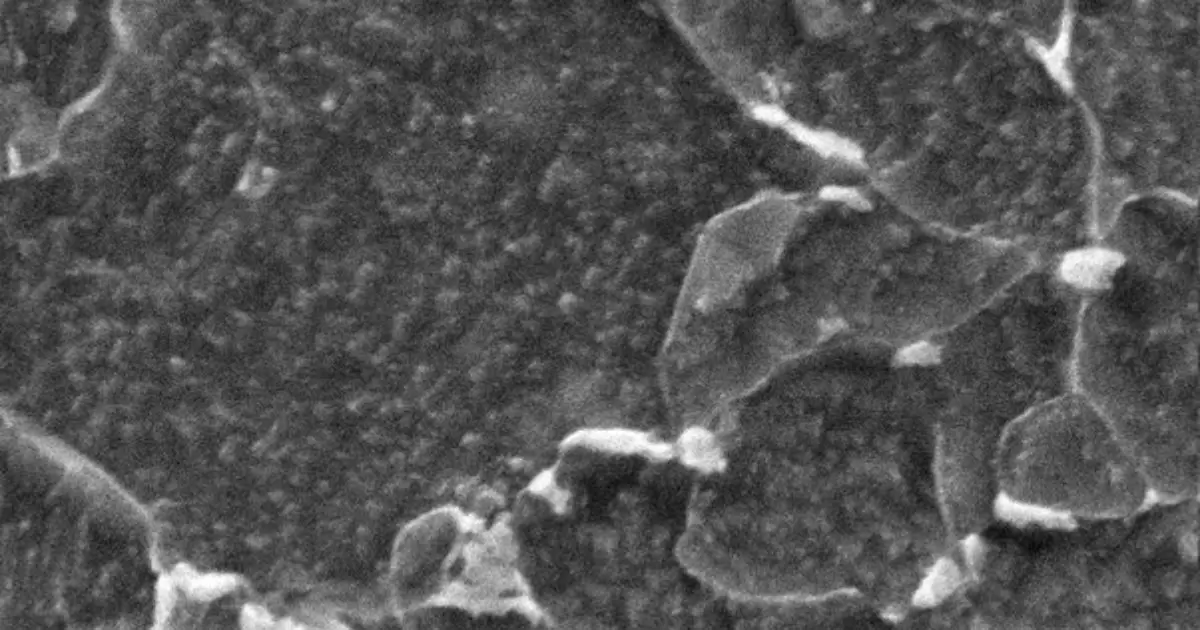

The Microscopic Perspective

Under microscopic exam, chrome steel unveils a fascinating crystalline structure made of grains. These grains are wonderful areas in which the crystal systems of the metals combined into the stainless steel align in various guidelines. Within these grains and alongside their edges, the awareness of introduced elements—like chromium or nickel—can fluctuate.

This variation introduces a diffused heterogeneity on the microscopic stage, despite the fabric’s homogeneous look to the bare eye. This microscopic range within the grains provides a complicated layer to understanding chrome steel’s universal uniformity and its famend homes which includes strength and corrosion resistance.

Composition of Common Stainless Steel Grades

Stainless metallic is not a single substance however an alloy made by using combining iron with chromium and different factors such as nickel, molybdenum, and carbon. The particular blend of those factors affects the metal’s houses and categorizes it into unique grades.

| Stainless Steel Grade | Iron (%) | Chromium (%) | Nickel (%) | Molybdenum (%) | Other Elements (%) |

| 304 | 66-74 | 18-20 | 8-12 | – | <2 (Mn, Si, C, N) |

| 316 | 62-68 | 16-18 | 10-14 | 2-3 | <2 (Mn, Si, C, N) |

The Composition and Homogeneity of Stainless Steel

The composition of stainless steel, particularly in popular grades like 304 and 316, demonstrates a significant level of uniformity across various samples, as indicated in the referenced table. This uniform distribution of factors which includes chromium, nickel, and molybdenum underpins the material’s consistent overall performance in realistic packages, making sure reliability where it subjects most.

Despite this apparent homogeneity, it’s vital to renowned the lifestyles of microscopic variations inside those steel grades. These small-scale differences, whilst not detracting from the steel’s average utility, add depth to our expertise of its structural and chemical make-up, highlighting the elaborate stability among uniformity and variability in its composition.

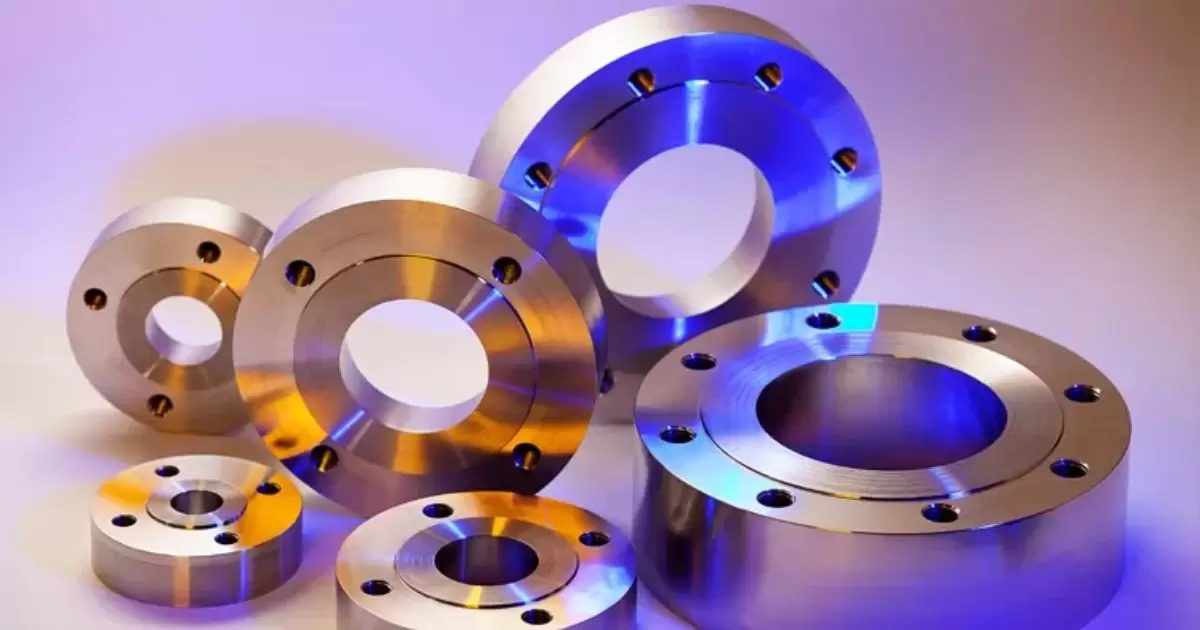

Applications and Implications

Stainless steel’s macroscopic homogeneity renders it essential in fields demanding unwavering consistency and dependability. Its uniform characteristics, spanning from strength to corrosion resistance, play pivotal roles in diverse sectors. Kitchenware and home equipment benefit from its durability and ease of cleansing, whilst inside the scientific realm, system and contraptions rely on its sterility and robustness.

Architecturally, chrome steel contributes to each the structural integrity and visible appeal of homes and monuments. This wide spectrum of programs underlines the cloth’s versatility, highlighting how its consistent quality across one-of-a-kind makes use of guarantees both useful reliability and aesthetic satisfaction in severa industries.

Microscopic Analysis of Stainless Steel

Upon nearer inspection via a microscope, stainless steel unveils a complicated internal global especially one of a kind from its reputedly uniform outside. This tricky microscopic panorama is characterized by way of a myriad of grains, each delineating a completely unique crystal structure and composition.

These grains are the microscopic constructing blocks of chrome steel, varying from one to some other, revealing the alloy’s diversity at this smaller scale. This granular shape is pivotal, as it underpins the material’s macroscopic properties, along with its electricity and resistance to corrosion, highlighting the sophisticated interaction between its microstructure and basic overall performance.

The Role of Alloying Elements

In the crafting of chrome steel, the addition of precise alloying elements is a deliberate and calculated process, pivotal to reaching its renowned houses. Chromium stands out as the hero for its critical function in bestowing chrome steel with its signature corrosion resistance. Nickel and molybdenum follow healthy, each contributing to the alloy’s more advantageous sturdiness and durability.

These factors, among others, are meticulously balanced to tailor the metal’s traits to its meant use. Grasping the importance of those factors is key to expertise not simply the uniformity of stainless steel on a macro scale, but also the nuanced interaction that presents it its awesome qualities.

Stainless Steel in Practice: A Homogeneous Mixture?

In practical terms, stainless steel’s uniform appearance and consistent properties across various applications firmly establish it as a homogeneous mixture. This homogeneity is essential for industries relying on the predictability of its traits, together with corrosion resistance, strength, and durability.

The even distribution of alloying elements like chromium, nickel, and molybdenum all through the fabric ensures that each piece of stainless steel meets the same high requirements required for its intended use. This segment delves into the significance of such uniformity, demonstrating how stainless-steel’s composition aligns with the criteria for homogeneity, making it an critical material in each everyday objects and specialized equipment.

Variations Within Stainless Steel Grades

The international of chrome steel is wealthy and sundry, with each grade tailored to fulfill unique software needs through distinct compositions. This tailored approach introduces a spectrum of diversity within chrome steel grades, every optimized for particular traits which includes stronger corrosion resistance, improved electricity, or progressed formability.

Such variation is vital for catering to the huge range of demands across industries, from production and automobile to kitchenware and medical gadgets. However, this variety additionally prompts a reevaluation of chrome steel’s homogeneity on a broader scale, considering how those compositional differences impact the perception and capability of stainless-steel as a unified fabric class.

FAQs:

Is stainless steel a homogeneous mixture or heterogeneous mixture?

Stainless metal is taken into consideration a homogeneous combination due to the fact its composition is uniform throughout.

What kind of mixture is a stainless steel?

Stainless metal is a type of homogeneous mixture referred to as an alloy, wherein metals are combined together uniformly.

Is steel a mixture or homogeneous?

Steel, including chrome steel, is a mixture and can be taken into consideration homogeneous at a macroscopic stage due to its uniform properties all through.

Is stainless steel a mixture True or false?

True, chrome steel is a aggregate.

Is stainless steel pure or a mixture?

Stainless metal is a aggregate. It is an alloy made by way of combining iron with chromium and different elements.

Why is stainless steel heterogeneous?

While chrome steel is normally considered homogeneous because of its uniform composition and houses in the course of, it could show off heterogeneity on a microscopic scale due to the distribution of its constituent elements and stages within the alloy.

Conclusion:

So, is stainless steel a homogeneous mixture? Based on the evidence, stainless steel should not be considered a homogeneous mixture. While it contains multiple metal elements blended together, including iron, chromium, nickel, and others, the crystal structure and composition are not consistent throughout on a microscopic scale.regions of different metals and non-metals are viewable under a microscope.

The mechanical, corrosion resistance, and other properties of stainless steel can vary in different regions depending on local composition. Instead, stainless steel alloys should be considered heterogeneous composites or hybrid materials. The various metals and metalloids are combined on a larger scale, but there are distinct localized regions with different properties and compositions within the overall alloy matrix.

The desired corrosion resistance and mechanical characteristics rely on the interactions between these heterogeneous phases. So in summary, while stainless steel blends various elemental ingredients, significant localized variability means it does not qualify as a truly homogeneous mixture at a microscopic level. The defining question remains – is stainless steel a homogeneous mixture? No, it is heterogeneous composite.