Stainless steel is a corrosion-resistant alloy composed generally of iron, chromium, nickel, and different factors. chrome steel dents can result in equipment damage over time. Getting dents out of the stainless steel method is the usage of strategies to restore dings, bumps, and harm to items made of this fabric.

Have you ever observed an irritating dent on your chrome steel equipment or cookware? Getting dents out of chrome stainless steel is feasible without replacing the item. Using clever tricks like dry ice or suction cups, dings can be nudged and coaxed to disappear. With some simple tools and techniques, dented stainless steel can look as good as new again.

Multiple methods exist for removing dents from stainless steel. Careful hammering or heating and cooling to make the steel more pliable allows dents to be worked out carefully from the other side. Suction cups can also pull dents outward. Severe dents may need professional metal workers using special tools to reshape the stainless steel without weakness.

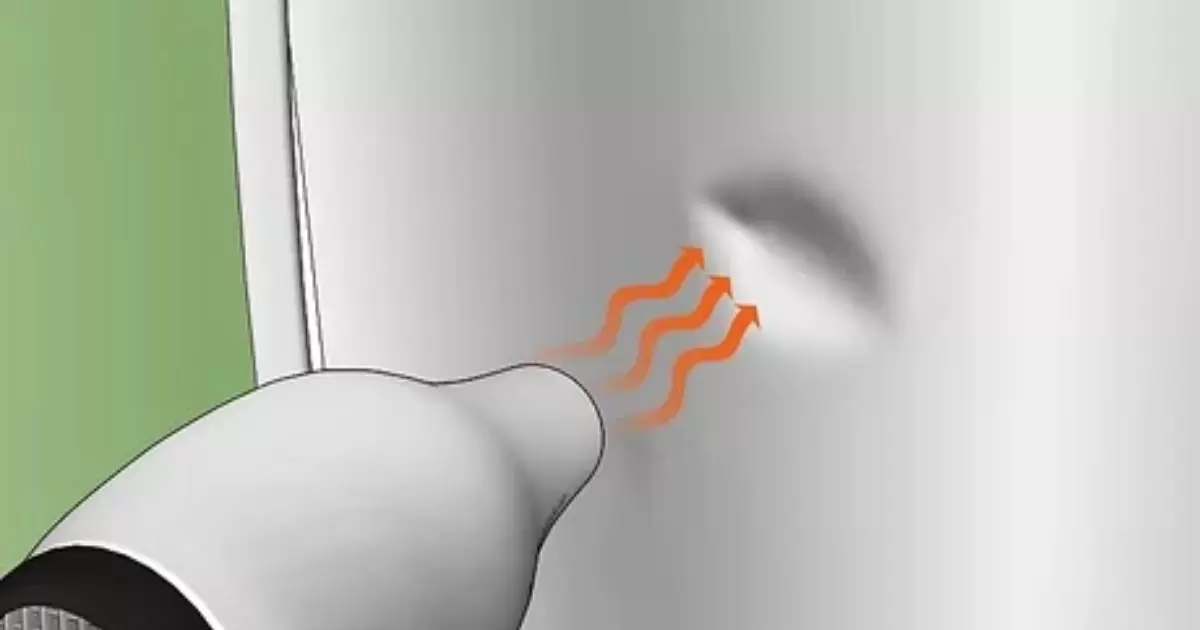

Heating and Cooling the Dented Area

Applying targeted heat or extreme cold to the stainless steel surface makes the metal more malleable. This allows dents to be carefully manipulated back into shape. Heat guns, hair dryers, or hot water can be used to warm and expand the steel. Dry ice is very effective at rapidly cooling to contract the metal. Caution should be exercised when handling hot or dangerously cold materials.

Suction Cup Dent Pulling

Suction cup dent pulling is a method to fix minor dings under 2 inches wide. First, clean the dented area well and let it dry. Then, use a hairdryer to lightly heat the dent, which makes the metal easier to reshape. Next, firmly attach the suction cup to the center of the deepest part of the dent. Gently pull the handle to draw the dent outward, working slowly from different angles. It’s important not to pull too hard, as this could harm the appliance lining.

Dry Ice Dent Popping

Dry ice dent popping is a method for removing small to medium stainless steel dents. First, protect your hands and eyes with heavy work gloves and eye protection. Then, wrap some dry ice in a cloth and apply it directly to the dent. Let the extreme cold work into the metal for 1-2 minutes. Afterward, remove the dry ice and gently tap the raised dent down flush from behind with a soft mallet or hammer. Repeat the process of applying cold and hammering until the dent smooths out.

Stud Welder Dent Pulling

Stud welder dent pulling is effective for medium and large stainless appliance dents. First, weld a screw stud securely to the deepest part of the dent using a stud welder. Then, attach the slide hammer and position it to pull directly outward. Firmly pull the hammer until the dent raises and smooths out. After that, twist or pry off the screw stud and sand the area smooth with 80-100 grit sandpaper. Next, fill the remaining hole with metal epoxy and let it fully cure. Finally, sand the epoxy patch flush once it has hardened.

When to Call for Professional Appliance Dent Repair

Knowing when to call for professional appliance dent repair is important. If you have large dents wider than 3 inches across or if your appliance has severe warping beyond the dent boundaries, it’s time to seek expert help. If there are holes in the metal or if the dents prevent doors or drawers from closing properly, professional repair is necessary.

Another sign to watch for is if the appliance is no longer sitting level due to the extent of the damage. Professional technicians have the commercial equipment needed to reshape the metal and address substantial damage that goes beyond what DIY methods can handle.

Preventing Dents in Stainless Steel Appliances

Preventing dents in stainless steel appliances is important for maintaining their appearance. During appliance delivery, install thick foam insulation panels and corner guards. Ensure appliances are correctly leveled and securely placed. Be cautious when opening cabinet doors and drawers to avoid hitting the appliances. Attach rubber bumpers to nearby cabinetry for added protection. Keep appliance exteriors clean to prevent scratching and damage from dirt.

Consider using stainless steel appliance covers for extra protection. With attention and care, your stainless steel appliances can stay looking new for years. However, if dents do occur, this guide provides techniques to try before considering appliance replacement. Another qeustion how to clean black stainless steel?

Pressing Out Dents from the Back Side

Pressing out dents from the back side is a method used to remove dents from stainless steel appliances. It involves accessing the back of the dent by removing exterior panels if necessary. Once the back side of the dent is accessible, proper support is placed underneath the dent to prevent further damage to the appliance. Rubber mallets or manual pressure are then used to gently push the dent outward from the inside.

This technique requires careful manipulation to avoid damaging any interior components of the appliance. By applying pressure from the back side of the dent, the metal is encouraged to return to its original shape. This method is particularly effective for some refrigerator or dishwasher dents where the interior structure allows for access to the back side of the dent.

it’s vital to work slowly and methodically, exerting just enough pressure to steadily push the dent outward without causing any additional damage. with the aid of pressing out dents from the returned side, it’s possible to repair the appearance of the stainless steel floor without the need for greater invasive repair methods.

Employing Suction Tools

using suction gear is a technique used to do away with dents from chrome steel surfaces. This approach includes the usage of equipment which includes suction cups, plungers, or vacuums that create a decent seal over the dent. these gear work by applying vacuum stress to the surface, which pulls the dent outward whilst launched.

To employ suction tools effectively, the dented area must be cleaned thoroughly and dried to ensure a proper seal. Additionally, heating the dent lightly with a hairdryer can make the metal more pliable, facilitating the removal process. Once the area is prepared, a suction cup is firmly attached over the deepest part of the dent.

With the suction cup in place, gentle pressure is applied by pulling the handle or activating the vacuum mechanism. The suction pulls the indentation outward when released, gradually working to restore the surface to its original shape. It’s important to work slowly and from different angles to achieve the best results.

Using Specialized Dent Repair Kits

One common tool found in specialized dent repair kits is the stud welder, which allows users to securely attach a screw or stud to the dent. Once the stud is welded in place, a slide hammer or puller is used to gradually pull the dent outward, restoring the surface to its original shape. This method is particularly effective for stubborn or deep dents in stainless steel appliances.

In addition to stud welders and slide hammers, specialized dent repair kits may also include metal epoxy for filling the remaining holes or gaps left behind after dent removal. The epoxy is applied to the affected location and allowed to absolute therapy earlier than being sanded clean to combo seamlessly with the surrounding surface.

Using specialized dent restore kits requires a cautious interest in the element and might contain a couple of steps to reap the preferred result. These kits are designed to provide users with the tools and materials necessary to effectively repair dents in stainless steel appliances, ultimately restoring them to their original condition.

Knowing When to Call a Professional

knowing when to call a professional for dent elimination from chrome steel home equipment is vital to make certain that the damage is properly assessed and repaired. while DIY methods may be powerful for minor dents, there are certain conditions wherein professional intervention is essential:

Extensive Damage: If the dent is good sized, covering a large location of the appliance, or if there are a couple of dents that require interest, it may be great to try to find the understanding of a professional. they have the knowledge and gear to address more complicated repair jobs efficaciously.

Large Dents: Dents wider than three inches across may be tough to restore using DIY techniques on my own. professional technicians have the enjoy to assess the extent of the harm and decide the maximum appropriate direction of motion for restoration.

Punctured Metal or Holes: If the dent has punctured the metal or if there are holes gift, it is crucial to seek advice from an expert. they could evaluate the damage and recommend first-class repair techniques to make sure the structural integrity of the equipment is maintained.

Dents Preventing Proper Functionality: If the dents save your doors or drawers from shutting well or if the equipment is no longer functioning because it should be due to the quantity of the damage, expert restore can be essential to restore functionality.

Significant Warping: If there may be huge warping past the boundaries of the dent, it can imply underlying structural troubles that require expert interest. trying to restore such harm without proper know-how may also get worse a hassle.

Preventing Dents in Stainless Appliances

at some point during appliance shipping and set up, use thick foam insulation panels and nook guards to protect prone areas of the appliance from damage. ensure that home equipment is successfully leveled and securely positioned in their exact places. proper installation can save your appliances from shifting or tipping, which may result in dents and harm.

Use caution while opening cupboard doors and drawers near chrome steel appliances to avoid by accident hitting or denting them. sluggish and careful movements can help prevent needless harm. connect rubber bumpers to adjacent cabinetry or partitions to provide a cushioning effect and protect appliances from unintentional influences.

keep equipment exteriors clean and free from particles. dust and filth can scratch the chrome steel floor, main to unsightly marks and capability corrosion over the years. don’t forget the usage of stainless-steel appliance covers to shield inclined fronts from dents, scratches, and other harm. those covers offer an extra layer of safety towards everyday wear and tear.

FAQs

Can you fix the dents in stainless steel?

yes, dents in stainless steel can frequently be fixed using techniques like making use of centered warmth or bloodless, pressing out the dent from in the back.

How do you fix a dent in a refrigerator?

For dents in fridges, attempt heating the region with a hairdryer then urgent the dent from the inner if viable.

How do you pop a dent out of steel?

To pop small dents out of steel, apply heat or intense cold to make the metal expand or contract, allowing the dent to rise.

How do you fix a dent in a stainless steel bottle?

For dents in stainless-steel bottles, fill the bottle with hot water and shake vigorously, then quickly press out the dent with the usage of padded pliers or urgent in opposition to a tender floor like a towel.

Do stainless steel bottles dent easily?

No, stainless steel bottles are quite durable and dent-resistant thanks to their hardy steel construction.

How do you fill dents in steel?

To fill dents in steel, use body filler products like Bondo glazing putty or metal epoxy. Clean, fill, smooth, prime, paint, and clear coat for best results.

Conclusion

Getting dents out of stainless steel items is possible using several effective techniques. For minor dents, manual approaches like hammering can raise the indent when applied properly to the opposite side. Medium dents require filling with stainless steel epoxy cleaning the area thoroughly and layering on filler material works well for a smooth finish after sanding.

Severe large dents need professional services, where technicians use specialized dent-pulling tools and metal heating to reshape the stainless steel structure without weakness. Prevention is also key using protective casings, installing bumpers on equipment, and handling all stainless steel carefully can prevent dents and damage in the first place.

But when dents inevitably do occur on stainless steel surfaces, remember there are cost-effective methods to restore the original appearance and integrity through dent removal. Tackling any stainless steel dent issues right away retains both visual appeal and longevity.