Grinding chrome steel is a vital approach in numerous industries, ranging from metalworking to fabrication and manufacturing. It includes doing away with fabric from the floor of the metal using abrasive gear, ensuring precise shaping, smoothing, or coaching for further processing.

Imagine remodeling a stupid, difficult piece of stainless-steel into a swish, polished masterpiece. Grinding chrome steel is an art form that needs precision, skill, and the proper techniques. Unlock the secrets and techniques to unlocking the real ability of this flexible metal and embark on a adventure of expertise.

From creating intricate designs to making ready surfaces for welding or coating, grinding chrome steel is a flexible system with programs throughout numerous sectors. Mastering the art of grinding can open doors to new opportunities, advanced performance, and superior nice on your metalworking projects.

Grinding Stainless Steel

Grinding stainless steel is a important system that includes removing fabric from the surface using abrasive tools. Whether you are shaping, smoothing, or preparing the steel for in addition processing, getting to know the artwork of grinding is essential for achieving specific and extremely good outcomes. In this comprehensive guide, we’ll discover the strategies, equipment, and first-rate practices for grinding chrome steel effectively. Another question of about, what is triply stainless steel?

Understanding Stainless Steel Properties

Before delving into the grinding system, it is vital to recognize the unique houses of stainless steel. This alloy is known for its corrosion resistance, strength, and sturdiness, making it a famous choice in diverse industries. However, the ones very houses moreover make chrome steel more difficult to grind in comparison to different metals.

Stainless metal’s hardness and work-hardening traits can cause excessive tool wear and warmth buildup all through grinding. Additionally, its low thermal conductivity can lead to localized overheating, which could compromise the cloth’s houses and surface finish.

Applications of Grinding Stainless Steel

Grinding stainless steel is a flexible system with a large range of applications across exclusive industries. In fabrication, it’s miles used for shaping, smoothing, and completing chrome steel additives which may be utilized in architectural or structural packages, making sure they meet the desired standards and aesthetics.

Within the equipment and system zone, grinding prepares surfaces for further methods collectively with welding, coating, or sharpening, playing a essential position in the production of enterprise machine. The automotive and aerospace industries depend on grinding for finishing and sprucing stainless steel elements, aiming to gain both aesthetic appeal and practical purposes.

Lastly, inside the medical and pharmaceutical fields, grinding is vital for developing easy, hygienic surfaces on surgical gadgets, implants, or processing machine, making sure they will be safe for use in medical strategies or drug manufacturing.

Tools and Equipment Required

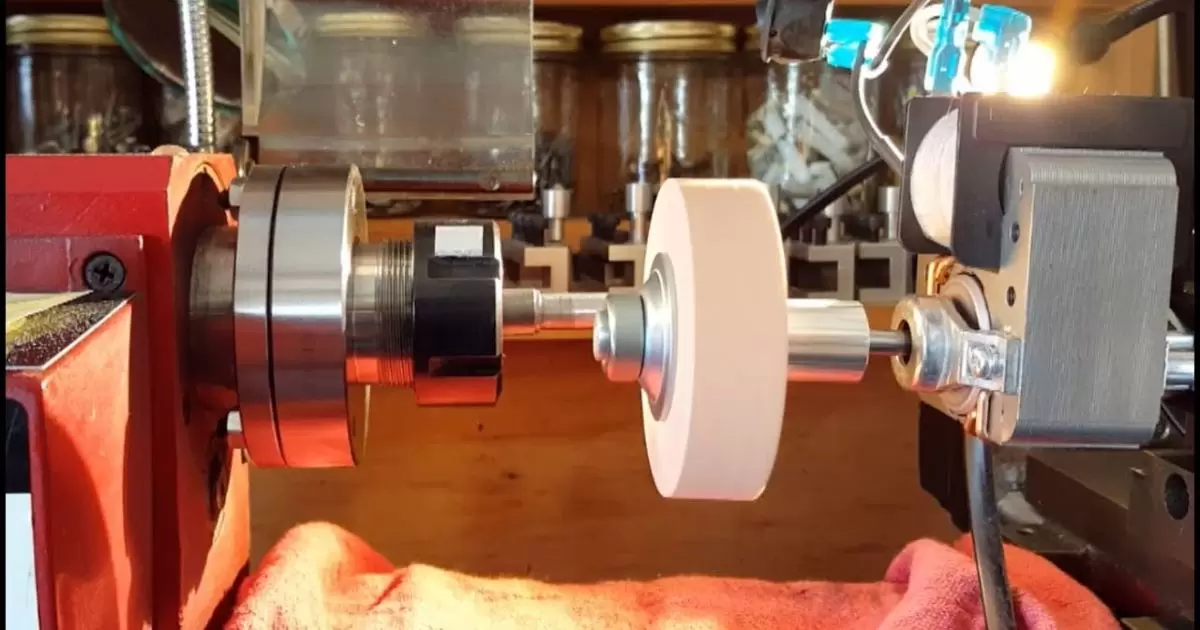

Common equipment for grinding chrome steel embody mind-set grinders with abrasive discs for aggressive fabric removal, belt grinders for smoothing big regions, and bench grinders with interchangeable wheels for various responsibilities. The abrasives used are typically aluminum oxide, zirconia, or cubic boron nitride (CBN) grinding wheels/discs in a single-of-a-type grit sizes from coarse (24-60 grit) to very high-quality (600 grit).

Preparation Before Grinding

Proper floor education is fundamental. Clean the chrome steel very well to do away with any dust, oil, rust, or debris that might have an effect at the grinding system. Deburr and take away sharp edges first to save you device damage. Select the right beginning grit size based totally on the amount of fabric to be eliminated and the preferred very last finish.

Safety Precautions

Grinding creates risks like flying particles, sparks, noise, and ability kickback. Always put on private shielding device (PPE) along with protection glasses, gloves, earplugs/muffs, and shielding garb. Ensure right ventilation or use a respirator to avoid breathing in harmful dust. Securely clamp the workpiece to save you motion throughout grinding.

Grinding Techniques for Stainless Steel

There are many ways, techniques and steps to grind stainless steel. For rough grinding, use coarser abrasives (24-60 grit) and apply moderate pressure in overlapping passes. For finishing, switch to finer grits (180-600) and use lighter pressure with smooth, consistent motions. Avoid dwelling in one spot to prevent overheating and discoloration. Maintain a 15-30 degree angle and keep the abrasive constantly moving.

Working with Different Shapes and Sizes

Flat surfaces can be ground using consistent side-to-side or up-and-down motions. For curves and edges, adjust the angle and apply the abrasive carefully to avoid gouging. Large pieces may require additional support or clamping. Small pieces should be held securely with locking pliers or a vise.

Temperature Management During Grinding

Stainless metal has low thermal conductivity, so it is crucial to control heat buildup. Use a consistent circulation of coolant (water-based totally or specialised reducing fluids) directed on the grinding place. Avoid excessive pressure and pause frequently to allow cooling. Signs of overheating include discoloration, warping, or a blue/rainbow tint on the surface.

Finishing Touches

For a mirror-like polish, progress through finer grit sizes (400-600) using light pressure and a consistent motion. Polishing compounds or rouge can be used with a soft cloth or buffing wheel for the final shine. Different finishes like satin, brushed, or bead-blasted can be achieved with specific abrasives or media.

Cleaning and Post-Grinding Care

After grinding, thoroughly smooth the surface with a degreaser or solvent to take away any residual coolant, particles, or sprucing compounds. Inspect for any remaining defects and address them as needed. Apply a protective coating or rust inhibitor if desired to preserve the finish.

Troubleshooting Common Grinding Issues

If discoloration occurs, try using a finer grit, lighter pressure, or more coolant. Uneven surfaces may require additional material removal or careful blending. Gouges or deep scratches can sometimes be repaired by re-grinding the area. If mistakes happen, consider starting over on that section.

FAQs:

Is stainless steel easy to grind?

No, chrome steel isn’t always clean to grind. It is more difficult and further abrasion-resistant than ordinary carbon steel, making it extra difficult to grind correctly.

What is the best abrasive for stainless steel?

The fine abrasives for grinding stainless steel are aluminum oxide, zirconia, and cubic boron nitride (CBN). CBN is considered the most effective for tough substances like stainless steel.

Is grinding stainless steel safe?

Grinding stainless steel may be secure if right safety precautions are taken. However, it can produce risks like flying debris, sparks, noise, and perilous dust, so carrying non-public defensive gadget (PPE) is crucial.

Which grinding wheel is used for stainless steel?

Aluminum oxide and zirconia grinding wheels are commonly used for grinding stainless steel. CBN (cubic boron nitride) wheels also are effective but more expensive.

What is the easiest way to grind stainless steel?

The easiest manner to grind chrome steel is to use the right abrasive wheels/discs (aluminum oxide, zirconia, or CBN), ok coolant, and proper strategies like warding off immoderate pressure and heat buildup.

What happens if you grind stainless steel?

When grinding stainless-steel, cloth is eliminated from the surface via the abrasive movement of the grinding wheel or disc.

Conclusion:

Grinding stainless steel is a important procedure that calls for precision, skill, and adherence to proper strategies. By expertise the precise homes of this material and the use of the right tools and abrasives, you could successfully grind chrome steel for numerous applications. The key to achievement lies in following satisfactory practices, which includes surface preparation, coolant utility, and preserving consistent motions.

Additionally, prioritizing safety by using sporting personal defensive equipment and enforcing proper ventilation is of maximum significance. When it comes to how to grind stainless steel? temperature management is a essential thing to prevent overheating, discoloration, and warping. Mastering the art of grinding chrome steel takes practice, however the rewards are nicely well worth the effort.

With precision and attention to element, you may reap superior results, whether or not you are shaping, smoothing, or getting ready stainless-steel surfaces for similarly processing. Embrace the mission, and unencumber the entire ability of this versatile and sturdy fabric.