The powder coating chrome steel method makes use of a dry, colored polymer powder to metal surfaces using an electrostatic spray gun. The metallic elements are then heated to soften the powder, which flows collectively to shape a clean, defensive coating. That is finished to trade the coloration of stainless steel or supply it better corrosion resistance.

Have you ever ever seen chrome steel that is not plain silver metallic? That is in all likelihood powder lined stainless steel. This process can add vibrant colorings and textures to chrome steel at the same time additionally making it greater long-lasting. However, how exactly does powder coating paint on stainless steel?

Powder coating stainless steel entails first cleaning and roughening up the floor so the powder will stick nicely. The powder is then sprayed on electrostatically and heated to melt it into a colored, protecting coating on the steel. This complements the appearance and sturdiness of chrome steel products.

Should You Powder Coat Stainless Steel?

Powder-coating stainless steel is recommended to gain enhanced aesthetics, extreme durability, easier maintenance, and other benefits over raw stainless steel. The upfront investment pays dividends in improved product lifetime and customer satisfaction.

What is Powder Coating?

Powder coating is a finishing process that applies a polymer powder to metal surfaces using an electrostatic charge. The powder is then cured under heat to form a smooth, protective coating.

Benefits of Powder Coating Stainless Steel

Applying a powder-coated finish to stainless steel components provides numerous advantages. The coating enhances aesthetics with vibrant colors and textures, improves durability and corrosion resistance, and makes products easier to clean and maintain.

How Powder Coating Works on Stainless Steel

Successfully powder coating stainless steel requires proper surface preparation including degreasing and abrasive blasting to remove contaminants and promote adhesion. The powder is then electrostatically applied before the parts undergo high heat curing to melt and harden the coating.

Best Applications for Powder-Coated Stainless Steel

From architectural features to commercial kitchens and laboratories, powder-coated stainless steel brings visual appeal and strengthened performance. It’s commonly used for railings, appliances, shelving, carts, furniture, playgrounds, robotics, and more.

An Introduction to Powder Coating

Before exploring powder coating specifically on stainless, it helps to understand what powder coating is and why it has become such a popular metal finishing process. Powder coating utilizes a dry, powdered polymer resin that is electrostatically applied to a part or product and then cured under heat to form a smooth, protective coating.

This combination of enhanced performance and flexibility has made powder coating the go-to finishing process for everything from automotive parts to bicycles, outdoor furniture, appliances, and industrial machinery. Powder-coated stainless steel allows these products to reap all the inherent benefits of stainless, while also gaining protection, durability, and aesthetic improvements. Is stainless steel recyclable?

Benefits of Powder Coated Stainless Steel

Applying powder-coated finishes to stainless steel components and products provides several significant benefits that make it an appealing finishing option:

Enhanced Aesthetics

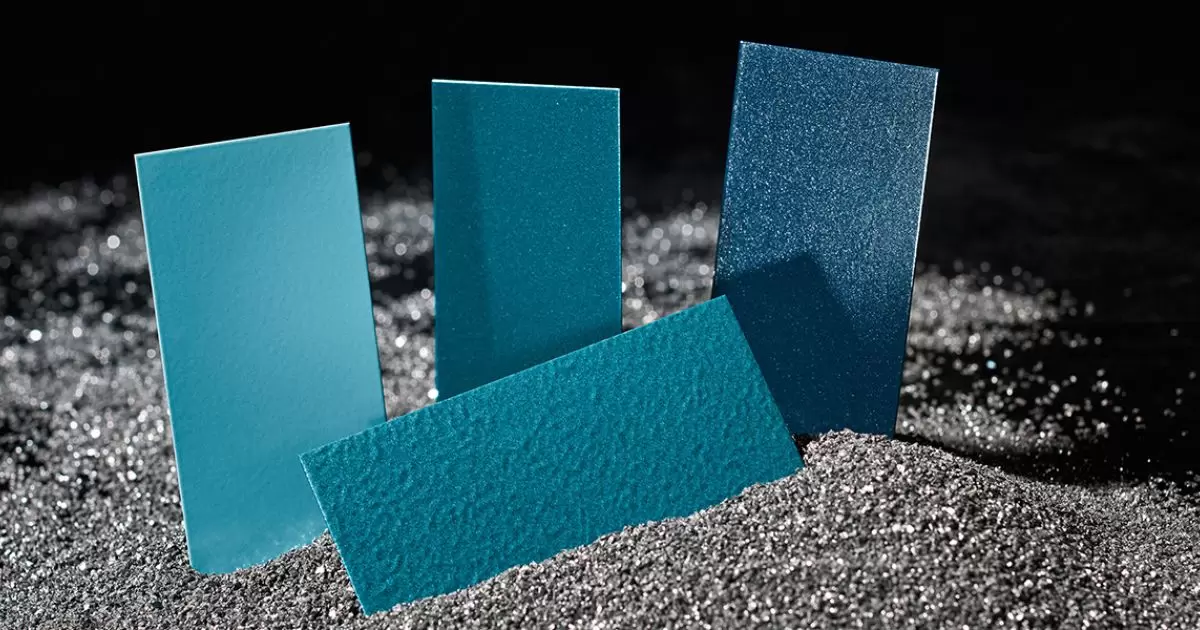

Powder coating offers virtually endless color and finish options to fit the exact needs of a product. Matte, gloss, metallic, wrinkled, textured, and more—if you can dream it, it can be created with a powder coat. This allows stainless steel parts to take on eye-catching colors and designs that attract attention.

Improved Durability

The powder-coated layer cured onto stainless steel resists scratching, scuffing, and abrasion much better than standard stainless steel alone. It also provides an extra barrier of protection against corrosion. This improved durability extends the service life of stainless products.

Easier Maintenance

The slick powder-coated surface repels water, dirt, grease, and more. This non-stick property keeps stainless steel components cleaner and looking for longer compared to uncoated stainless, while also being easier to clean when needed.

How to Powder Coat Stainless Steel

Successfully powder coating stainless steel requires a series of key steps to ensure proper adhesion and performance:

Surface Preparation

Meticulous surface prep is crucial for the powder to bond correctly to stainless steel. The surface must be thoroughly cleaned of any oils, dirt, and residue using alkaline cleaning solutions. Media blasting then roughens up the surface to enable mechanical adhesion and provide a tooth for the powder to cling to.

Common media blasting materials include:

- Aluminum oxide

- Glass beads

- Walnut shells

- Plastic pellets

- Sodium bicarbonate

This aggressive roughening also removes any external corrosion that could cause early failure of the coated finish.

Powder Application

With the substrate properly pretreated, the powder coating material can now be applied using either a spray gun or a fluidized bed dipping process. Spraying electrostatically charges the powder so it wraps around and clings to all surfaces of a part. The dipping method fully submerges items into a bed of air-fluidized powder—great for coating small parts.

Baking

Once fully coated in powder, the stainless steel parts enter high-temperature ovens to melt, flow out, gel, and cure the powder into a smooth, uniform, protective finish. Temperatures typically range from 300° to 400° F depending on the powder’s chemistry. The length of time needed for full cure also varies by powder type, from just 10 minutes up to one hour. Proper baking is crucial to create finishes that achieve maximum hardness and durability.

Applications for Powder Coated Stainless Steel

Stainless metal, while more desirable with powder lined finishes, combines the sturdiness of stainless-steel with the addition of colourful colours, textures, and stepped forward protection. This mixture makes powder lined stainless-steel an fantastic choice for a big selection of makes use of. It is highly sought after for decorative architectural accents such as railings, bollards, and screens.

In the realm of food service, it finds applications in restaurant and kitchen equipment including appliances, work tables, and shelving. It is likewise ordinary in industrial restrooms, where it’s far used for walls, furniture, dispensers, and waste cans. In healthcare and scientific settings, powder lined chrome steel is applied for medical institution and laboratory equipment like carts, shelves, and fume hoods.

The transportation sector benefits from it in the form of hitches, running boards, and trim. Furthermore, it serves a variety of purposes in furniture making for both indoor and outdoor items, including desks, cabinets, and racks. Retail displays also take advantage of this material for racks, hooks, and sign frames.

Beyond these applications, powder coated stainless steel is employed in exercise and playground equipment, as well as in industrial machinery, tools, and robotics. Essentially, its uses are nearly limitless, with the right surface preparation and coating process allowing stainless steel products to achieve performance benefits far exceeding those of mill finish stainless steel alone.

Should You Powder Coat Stainless Steel?

If you manufacture or purchase products made from stainless steel, having them powder-coated by a professional finisher is worth considering. It enables vibrant colors that attract attention paired with enhanced durability to withstand years of use and abuse in demanding settings.

While powder coating does entail some upfront costs over raw stainless steel, for manufacturers it significantly expands the value and sales appeal of products. And for end users, the improved aesthetics, performance, and longevity justify the initial investment.

So if unique visuals, hardcore durability, and corrosion resistance matter for your stainless steel components and products, powder coating is a definite “yes!” It delivers exceptional aesthetics and protection that no other coating method can match. Your products gain far more beauty, strength, and market appeal.

Benefits of Powder Coated Stainless Steel

Some of the major advantages of powder coating stainless steel include:

- Vibrant and unique colors and textures

- Enhanced scratch and corrosion resistance

- Easier cleaning and maintenance

- Overall improved durability and longevity

Powder coating can transform ordinary stainless steel into a visually striking and stronger finished product.

Process of Powder Coating Stainless Steel

Successfully applying powder coating to stainless steel requires carefully following these key steps:

Surface Preparation

The procedure of making use of powder coating to stainless steel involves several critical steps to ensure a a success and sturdy end. The first step, surface practise, is essential. It includes thoroughly cleansing and degreasing the chrome steel surface to do away with any impurities. Following cleansing, media blasting is used to do away with contaminants similarly and roughen the floor, making sure the powder coat will adhere nicely.

Powder Coating Application

Once the floor is prepared, the powder coating application begins. This step includes electrostatically spraying the powder directly onto the elements to be coated. It’s important to absolutely coat all surfaces lightly to acquire a uniform end.

Baking/Curing

After the application of the powder coat, the following step is baking or curing. This technique entails heating the components to soften the powder coating, which then treatment plans to form a strong layer. The usual temperature variety for this procedure is among three hundred°F and 400°F, and the cycle time can vary from 10 mins up to one hour, relying on the particular necessities of the powder coating cloth and the thickness of the utility.

Proper surface prep and powder application allows powder coats to fully bond to stainless steel.

Pros and Cons of Powder-Coated Stainless Steel

| Pros | Cons |

| Attractive colors and textures | Surface imperfections show through |

| Extreme durability | Susceptible to chips/impacts |

| Enhanced corrosion resistance | Added cost over raw stainless |

| Easy maintenance | Production lead times increase |

| Environmentally friendly |

FAQs:

Should you powder coat stainless steel?

Yes, you can powder coat stainless steel to add color, texture, and enhanced corrosion resistance over the natural silver finish. It improves aesthetics and durability.

How long does powder coating last on stainless steel?

Powder coating can last 15-20 years on stainless steel, depending on the pre-treatment and type of powder coating used. It provides long-lasting protection.

What metal Cannot be powder-coated?

Magnesium and zinc cannot be powder coated because they cannot withstand the high curing temperatures required to cure the powder coating.

Can you put a coating on stainless steel?

Yes, stainless steel can have coatings like paint, powder coating, or iron armor applied to it to change its color and provide additional corrosion resistance.

What is the best coating for stainless steel?

Powder coating provides the most durable, attractive, and corrosion-resistant finish for stainless steel compared to paints or other coatings.

Can you powder coat 304 stainless steel?

Yes, grade 304 stainless steel is commonly powder coated to give it vibrant colors and enhanced protection while retaining its inherent strength and corrosion resistance.

So can you powder coat stainless steel?

Applying a powder-coated finish to stainless steel components comes with numerous benefits that make it an appealing option over raw stainless steel in many applications.

Conclusion:

Powder coating allows stainless steel parts to gain incredible aesthetic and performance benefits beyond what mill-finish stainless steel alone can provide. With vibrant colors and enhanced durability, powder-coated stainless steel is an exceptional choice for creating eye-catching, long-lasting products.

The resulting powder-coated stainless steel stands up better aesthetically and functionally over time compared to mill-finished stainless. While powder coating does come with some drawbacks like higher costs and production lead times, in the end, the visual customization and extreme scratch and corrosion resistance justify the investment for manufacturers and end users alike.

So if unique visuals, exceptional durability, easier maintenance, and corrosion protection are important for your stainless steel parts and products, powder coating can grant all of that, elevating ordinary stainless to a higher level. can you powder coat stainless steel? Yes, you absolutely can powder coat stainless steel to transform the look and performance of this versatile metal.