Bending stainless-steel involves shaping the metal into extraordinary contours and curves. It is a metalworking technique where the chrome steel is manipulated to alternate its form with out breaking. Stainless metal is a strong fabric that can be tough to completely regulate through bending.

Have you ever wondered how it’s miles feasible to bend chrome steel into unique shapes? Stainless metallic seems like this sort of rigid and sturdy fabric that holds its shape properly. With the right techniques and tools, it could be bent into curved shapes wanted for diverse industrial and architectural programs.

Bending stainless steel calls for warmness and pressure. The stainless-steel must be sufficiently heated to grow to be more malleable and pliable earlier than bending it into the preferred form. Specialised bending gear and machines are used as properly to lock the bend into the metallic after shaping while it cools. With a combination of heat, force and the right device, stainless-steel can in fact be manipulated into everlasting bends and curves.

What Equipment Is Needed To Bend Stainless Steel?

There are a few important types of equipment required to successfully bend stainless steel. First, a stainless steel bender is needed to apply the force and lock the bend in the metal. Manual benders involve leverage and wheels to shape the steel. Mechanical benders provide more consistent bends but require more space. Hydraulic benders offer precision bending of various metals sizes and thicknesses.

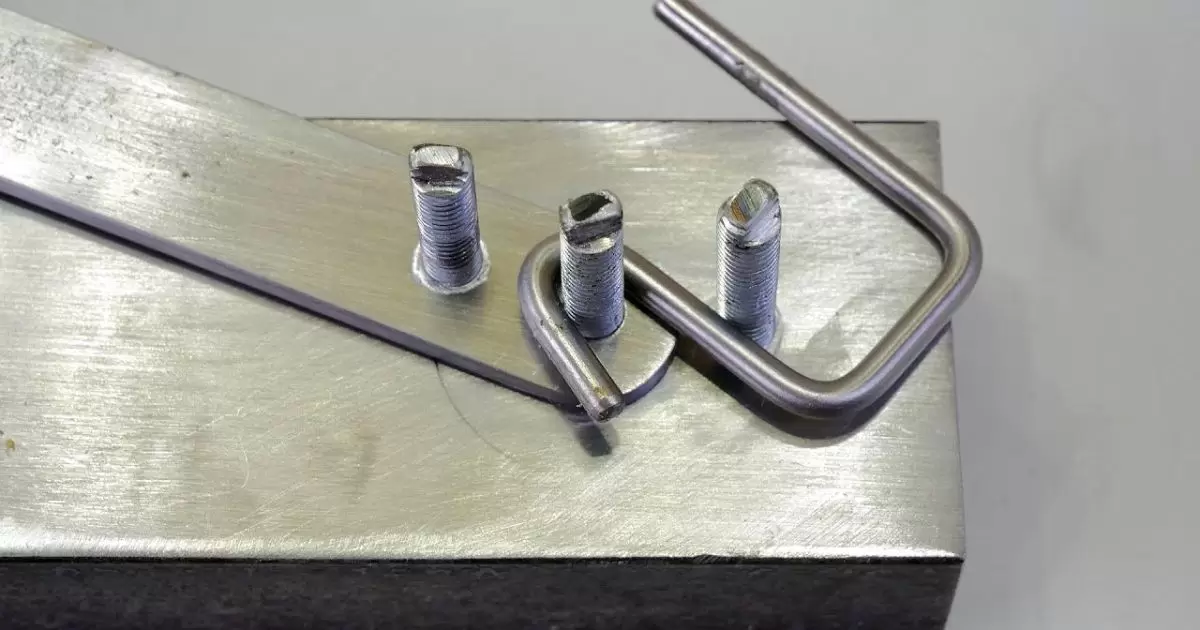

Some essential bending tools consist of mandrels, bending blocks, and clamps. Mandrels are used inside tubing and hollow sections to prevent kinking and maintain the shape during bending. Bending blocks provide a hard surface to support the steel while bending. Clamps securely hold the metal in place. Other helpful tools are hammers, metal shears, deburring tools, and safety glasses for metalworking.

Heat assets like oxy-acetylene or MAPP gasoline torches are critical to raise the stainless steel’s temperature. Proper safety device like heavy gloves, leather apron, and defensive masks should always be worn for hearth and heat protection while bending stainless-steel. With the proper bending equipment and tools, any metal shop can form curves in stainless steel.

How Does Heating Affect Bending Stainless Steel?

Stainless metallic is stronger and tougher than mild metal so it wishes to be heated to soften it before bending. When chrome steel is heated, its crystalline shape adjustments and will become greater malleable, allowing it to be smoothly bent into shapes.The metal working is easier and less force is required compared to cold working. Heating also relieves internal stresses built up during bending.

Determining the correct temperature is important. If it’s too cool, the steel may crack rather than bend. Yet if it’s too hot, the grain structure could be damaged or flames may warp or discolor the surface. Most stainless grades are heated to a light yellow-orange heat of roughly 1500-1700°F. An infrared thermometer helps ensure consistent heating. Uneven heating can result in an inconsistent bend or cracks.

Once bent, quick cooling prevents further work hardening. Cooling methods include air, water or allowing the bent steel to cool slowly in still air. Proper heating method and temperature is important for achieving quality, long-lasting bends in stainless steel. what is brushed stainless steel?

What Bending Techniques Work Best For Stainless Steel?

There are a few main techniques used to bend stainless steel successfully. Roll bending involves passing the heated steel between large rollers to shape tight radius bends. It’s best for longer runs with consistent curvature. Brake pressing bends steel manually or mechanically by applying pressure with a brake tool over a die block. It can produce short-radius and compound angle bends better than rolls.

Using mandrels is critical when bending tubing. A mandrel inserted inside maintains the tubing’s circular shape during bending. This prevents kinks and collapse. Mandrels come in various diameters sized for the tubing wall thickness. Thin stainless steel requires different handling to avoid cracks.

It may need to be wrapped in fiber to add rigidity or a backup strip used under the bend area for support during forming. Starting with a gentle bend and working slowly is best. With the right selection of roll bending, braking or mandrel techniques, intricate bends can be shaped in stainless steel.

How Can The Bend Quality Be Ensured?

It is important to properly inspect bends in stainless steel to catch any issues. Cracks in the steel are unacceptable. Carefully check the outside and inside of bends under good lighting soon after forming while still warm. Even small cracks can weaken the material over time. Sanding and dying the steel makes cracks easier to spot. Work hardening occurs when cold-bending stainless steel, making it more prone to cracking.

This effect is relieved by carefully heating the steel adequately according to guidelines before bending. Re-heating hardened steel brings it back to an easier-to-form condition. Consistent heat and a gradual bending process without sharp angles creates smooth, long-lasting curves. Quality control involves verifying dimensions and tolerances of finished bends.

Templates can be used for reference checks. Checking 5-10% of total bends helps identify any problems requiring adjustments to techniques or equipment. Documentation of procedures, materials and required checks ensures standards. Repeated inspections catch minor variation from specifications before issues arise. Together, these steps provide durable, high-quality bends in stainless steel for various applications.

What Applications Require Bent Stainless Steel?

Stainless steel tubing is often bent into shapes needed for appliances, industrial machinery and scientific equipment. Curved tubes are used for water lines in dishwashers or refrigerant lines in air conditioners. Bent legs or frames give sturdy but stylish forms to lab tables and surgical tools. Furniture like chairs, racks and shelving use bent steel elements. Precise bends feature strongly in durable equipment construction.

Architectural elements like partition dividers, sculptural balustrades and ornamental handrails employ the corrosion resistance and style of stainless steel. Subway entrances, outdoor signage and balcony railings employ intricate bends. Auto manufacturers also depend on predictable bending to shape heat-resistant exhaust piping down to tight spaces.

Medical tools such as retractors, clamps and scopes contain complexly bent tubing and casings for high functionality in delicate procedures. When durability and hygiene in demanding environments are required, stainless steel is often chosen and formed through bending.

| Equipment | Purpose |

| Bender | Applies force to shape and lock in the bend |

| Heating Torch | Raises steel temperature for bending |

| Mandrels | Inserted inside tubes to prevent kinking |

| Bending Blocks | Provide hard surface for support |

| Clamps | Hold steel securely in place during bending |

| Safety Gear | Protection from heat, fire and sharp edges |

Basics And Challenges Of Bending Stainless Steel Tubing

Bending stainless steel tubing requires careful consideration of the material’s properties and the right techniques to avoid ovalization, wrinkling, or cracking. The process typically involves using a tube bender with a precisely machined groove that matches the tube’s outer diameter. Proper support and alignment of the tubing within the bender is crucial to prevent deformation.

Factors just like the tubing’s wall thickness, bend radius, and the diploma of the bend can significantly impact the problem of the operation. Stainless steel’s high strength and paintings-hardening dispositions pose demanding situations, regularly necessitating using specialized bending lubricants, mandrels, or filler materials to preserve the desired shape and integrity of the tubing at some stage in the bending manner.

FAQs:

How do you bend stainless steel at home?

Use a hand-held propane torch to heat the metallic gradually to 1500-1700°F and slowly bend it over a strong surface using pliers or a wrench.

Do you heat stainless steel to bend it?

Yes, stainless-steel needs to be heated to soften it and make bending less difficult without cracking the metallic.

Is stainless steel easily bendable?

Stainless metallic is more potent than slight metal so it requires greater warmth and pressure to bend. With the right tools and heating, it can be permanently bent.

Can stainless steel be bent back?

Once stainless-steel is bent, it cannot reliably be bent back to its authentic form with out paintings hardening or cracking.

How do you soften stainless steel to bend?

Heating the steel with a torch to 1500-1700°F softens its crystalline structure, bearing in mind bending at that temperature without harm.

Is stainless steel harder to bend?

Yes, stainless steel has stronger corrosion resistance but less ductility than mild steel, so it takes more heat application and leverage effort to successfully bend. Proper techniques are needed.

Conclusion:

Bending stainless steel requires persistence, ability, and the proper equipment. The key to a hit bending lies in knowledge the fabric’s houses, getting ready the workpiece effectively, and using the suitable bending strategies. Whether you’re the usage of a press brake, a bending fork, or a rolling device, keeping manage over the bend radius and minimizing distortion is vital.

How to bend stainless-steel? May be spoke back by means of following the stairs of selecting the proper grade of stainless-steel, marking the bend line as it should be, the use of a bending fixture or die, making use of consistent strain, and bearing in mind springback.

With practice and interest to element, all and sundry can master the art of bending chrome steel for diverse programs, from architectural metalwork to industrial fabrication. Remember, safety have to continually be the pinnacle priority while working with this durable yet unforgiving cloth.