Tungsten enhances the strength and durability of stainless steel. It’s like adding a superhero to a team, making stainless steel tougher and more resistant to wear and corrosion. With tungsten, stainless steel becomes a reliable material for tools, machinery, and even jewelry, ensuring they last longer and perform better.

Imagine you have a secret ingredient that makes everything stronger and tougher. That’s what tungsten does for stainless steel. It’s like asking, ‘What tungsten for stainless steel?’ Tungsten swoops in and boosts stainless steel’s powers, making it a mighty material for all sorts of things.

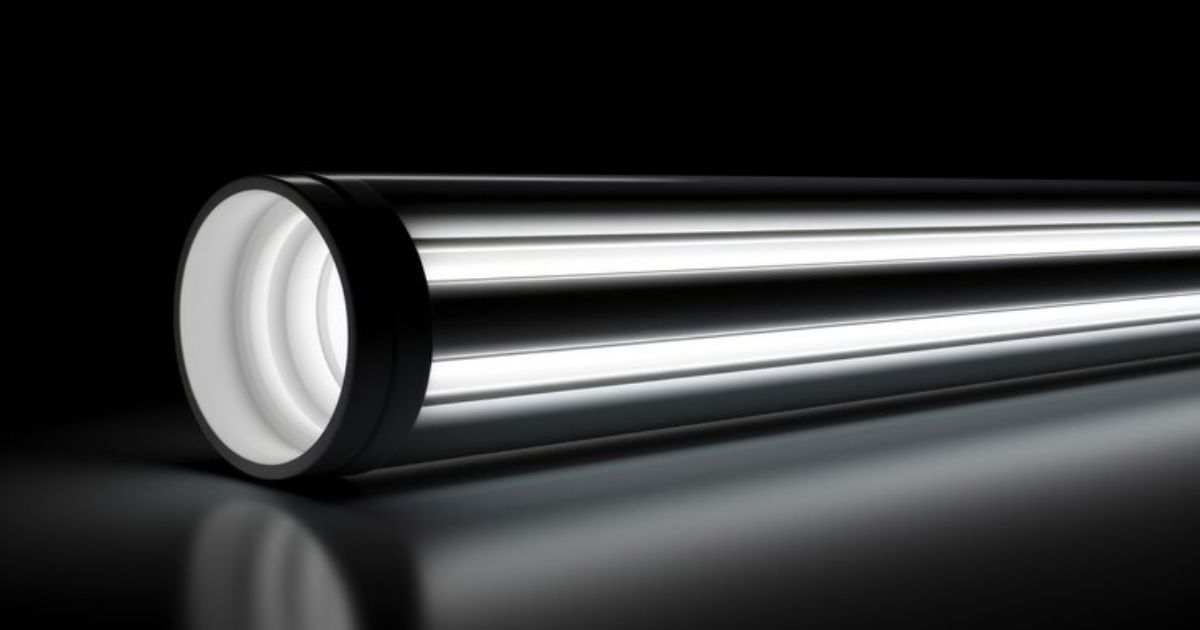

What tungsten for stainless steel? Tungsten is like the knight in shining armor for stainless steel. It strengthens the steel, making it more resistant to damage and corrosion. So, when you see tungsten in stainless steel, you know it’s going to be tough and reliable, whether it’s in your kitchen or in machinery.

Tungsten and Stainless Steel

Tungsten is a strong metal often used to enhance the properties of other materials, like stainless steel. Stainless steel, on its own, is already corrosion-resistant and versatile. But when you add tungsten to the mix, it becomes even stronger and more durable.

The Role of Tungsten in Strengthening Stainless Steel

Tungsten acts as a reinforcing agent in stainless steel, similar to how steel rods strengthen concrete. It improves the steel’s hardness, strength, and resistance to wear and tear. This makes tungsten-modified stainless steel ideal for applications where toughness and longevity are essential, such as in industrial machinery and tools. how to remove tea stains from stainless steel?

Applications of Tungsten-Enhanced Stainless Steel

Tungsten-strengthened stainless steel finds its way into various industries. From aerospace components to surgical instruments and even high-performance sports equipment, the enhanced durability and resistance to corrosion make it a preferred choice for critical applications where reliability is paramount.

Advantages of Using Tungsten in Stainless Steel

The incorporation of tungsten into stainless steel brings several benefits. It extends the lifespan of products, reduces maintenance needs, and enhances performance under harsh conditions. Additionally, tungsten-modified stainless steel can withstand extreme temperatures, making it suitable for a wide range of environments.

Challenges and Considerations in Tungsten-Modified Stainless Steel Production

While tungsten offers significant advantages, its integration into stainless steel comes with challenges. The production process can be complex and expensive, requiring precise control over alloy composition and manufacturing conditions. Moreover, tungsten’s high density and hardness may pose machining difficulties.

Future Outlook and Innovations in Tungsten-Stainless Steel Composites

Researchers and engineers are continually exploring ways to optimize tungsten-stainless steel composites. Innovations in alloy design, manufacturing techniques, and surface treatments aim to further enhance performance and expand potential applications. As technology advances, we can expect tungsten-modified stainless steel to play an increasingly vital role in various industries.

Enhancing Stainless Steel’s Mechanical Properties

Tungsten’s incorporation into stainless steel alloys can significantly improve the metal’s mechanical properties, such as tensile strength, hardness, and resistance to wear and corrosion. This makes it a crucial component in the manufacturing of tools, machinery, and other industrial applications that require durable and long-lasting materials.

Improving Stainless Steel’s Thermal Resistance

The presence of tungsten in stainless steel alloys can also enhance the material’s thermal resistance, allowing it to withstand high temperatures without compromising its structural integrity. This makes tungsten-alloyed stainless steel highly valuable in applications that involve exposure to extreme heat, such as in the aerospace and automotive industries.

Exploring the Versatility of Tungsten-Alloyed Stainless Steel

Tungsten-alloyed stainless steel can be tailored to meet a wide range of specific requirements, making it a versatile choice for various industries. By adjusting the composition and processing methods, manufacturers can create stainless steel alloys with unique properties that cater to the specific needs of their applications.

How Tungsten Enhances Stainless Steel’s Strength

Tungsten’s high atomic weight and its ability to form strong covalent bonds with iron and other alloying elements contribute to the increased strength of stainless steel. This strengthening effect is particularly pronounced in the presence of other alloying elements, such as chromium and nickel, which are commonly found in stainless steel.

Tungsten’s Role in Stainless Steel’s Corrosion Resistance

In addition to enhancing the mechanical properties of stainless steel, tungsten also plays a role in improving the alloy’s resistance to corrosion. Tungsten can help form a more stable and protective passive oxide layer on the surface of the stainless steel, which helps to prevent the onset of corrosion and pitting.

The Unique Challenges of Tungsten-Alloyed Stainless Steel

While the addition of tungsten to stainless steel can bring numerous benefits, it can also present some unique challenges in terms of fabrication and processing. The high melting point of tungsten, for example, can make it more difficult to weld or machine the alloy compared to standard stainless steel compositions.

Understanding the Specific Needs of Your Application

When choosing a tungsten-alloyed stainless steel, it is essential to consider the specific requirements of your application, such as the expected mechanical loads, operating temperatures, and exposure to corrosive environments. This will help you select the most appropriate alloy composition and processing methods to meet your needs.

Evaluating the Cost-Benefit Ratio of Tungsten-Alloyed Stainless Steel

While the addition of tungsten can enhance the performance of stainless steel, it can also increase the overall cost of the material. It is important to carefully evaluate the cost-benefit ratio to ensure that the improved properties of the tungsten-alloyed stainless steel justify the higher price.

Consulting Experts for Guidance on Tungsten-Alloyed Stainless Steel

Selecting the right tungsten-alloyed stainless steel for your application can be a complex process, and it is often advisable to consult with experts in the field. These experts can provide guidance on the most suitable alloy compositions, processing methods, and fabrication techniques to ensure the optimal performance and long-term reliability of your stainless steel components.

Staying Up-to-Date with Advancements in Tungsten-Alloyed Stainless Steel

The field of tungsten-alloyed stainless steel is constantly evolving, with new research and development leading to the introduction of improved alloy compositions and processing methods. It is important to stay informed about the latest advancements in this area to ensure that you are using the most advanced and cost-effective materials for your applications.

FAQs:

Which tungsten is best for stainless steel?

Tungsten-based alloys with higher percentages of tungsten (typically around 2-4%) are generally considered the best for use in stainless steel.

Is red tungsten good for stainless steel?

Red tungsten, also known as thoriated tungsten, is not typically recommended for use in stainless steel.

What is E3 tungsten used for?

E3 tungsten is a type of tungsten electrode used in gas tungsten arc welding (GTAW) or TIG welding.

Can you weld stainless steel with blue tungsten?

Yes, blue tungsten (also known as zirconiated tungsten) can be used to weld stainless steel.

What tungsten is best for stainless and mild steel?

For welding both stainless steel and mild steel, a versatile option is thorium-free lanthanated tungsten electrodes.

Why is tungsten added to stainless steel?

Tungsten is added to stainless steel to enhance its mechanical properties, such as strength, hardness, and wear resistance.

Conclusion:

In conclusion, the addition of tungsten to stainless steel brings about a remarkable transformation, elevating its properties to new heights of strength, durability, and corrosion resistance. This partnership between two formidable materials opens doors to a myriad of applications across diverse industries, from aerospace engineering to everyday household items.

Despite the challenges in production and machining, the benefits far outweigh the obstacles, offering extended product lifespan, reduced maintenance costs, and enhanced performance in demanding environments. As we look to the future, ongoing research and innovation hold promise for further advancements in tungsten-stainless steel composites, paving the way for even more robust and versatile materials.

In essence, the question of what tungsten for stainless steel? underscores not just a chemical addition, but a strategic alliance that propels stainless steel into realms of strength and reliability previously unattainable.