A plasma cutter is a device that uses a totally warm, focused beam to cut through metal. Stainless metal is a sort of metallic that resists rust and stains. Plasma cutters can reduce stainless-steel because of the fact the current plasma beam is powerful sufficient to soften via the difficult stainless floor. The proper settings want for use so the reduce is simple and precise.

Can a effective plasma cutter slice cleanly thru hard stainless steel? With severe heat up to 30,000°F, plasma cutters melt and cut many metals. Adjusting the settings permits, will a plasma cutter reduce stainless-steel? To be reduce easily and correctly. Read on to learn how it really works?

Plasma cutters are first rate tools that use exquisite warm plasma to reduce steel. Stainless steel may be very difficult and robust. But with the proper strategies, even chrome steel can be reduce via a plasma cutter. This article explains a way to reduce stainless steel and what settings to apply for the high-quality results.

What is Stainless Steel?

Stainless steel is a collection of metal alloys containing as a minimum 10.Five% chromium content. The chromium creates a thin, invisible layer of oxidation on the steel’s floor that protects it from rust and corrosion. Other alloying factors like nickel and molybdenum will also be delivered to decorate characteristics like formability, weldability, and temperature resistance. And also one thing why is stainless steel so expensive?

There are many unique grades of stainless-steel, but the most common types utilized in production and production are:

304: Also called 18/eight stainless, it consists of 18% chromium and eight% nickel. 304 is the maximum flexible and widely used stainless steel.

316: The addition of two-3% molybdenum improves corrosion resistance, making 316 appropriate for marine and pharmaceutical programs.

410: A widespread motive martensitic chrome steel that is warmth treatable, machinable, and reasonably-priced.

430: Most broadly used ferritic stainless-steel, regularly utilized in car trim and home equipment. More corrosion resistant than 410.

Duplex steels: Offers a combination of austenitic and ferritic microstructures for energy and corrosion resistance. Common in chemical processing.

What is a Plasma Cutter?

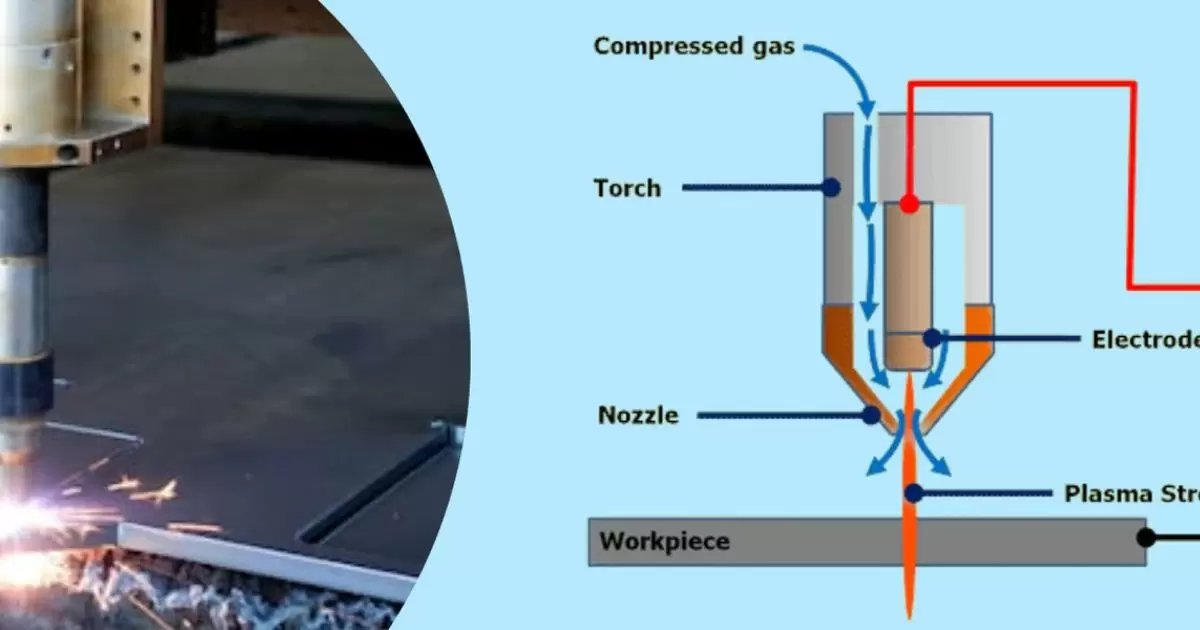

A plasma cutter is an business metallic cutting device that uses a constricted arc of ionized gas to soften and cut thru conductive metals like steel, stainless steel, aluminum, brass, and copper.

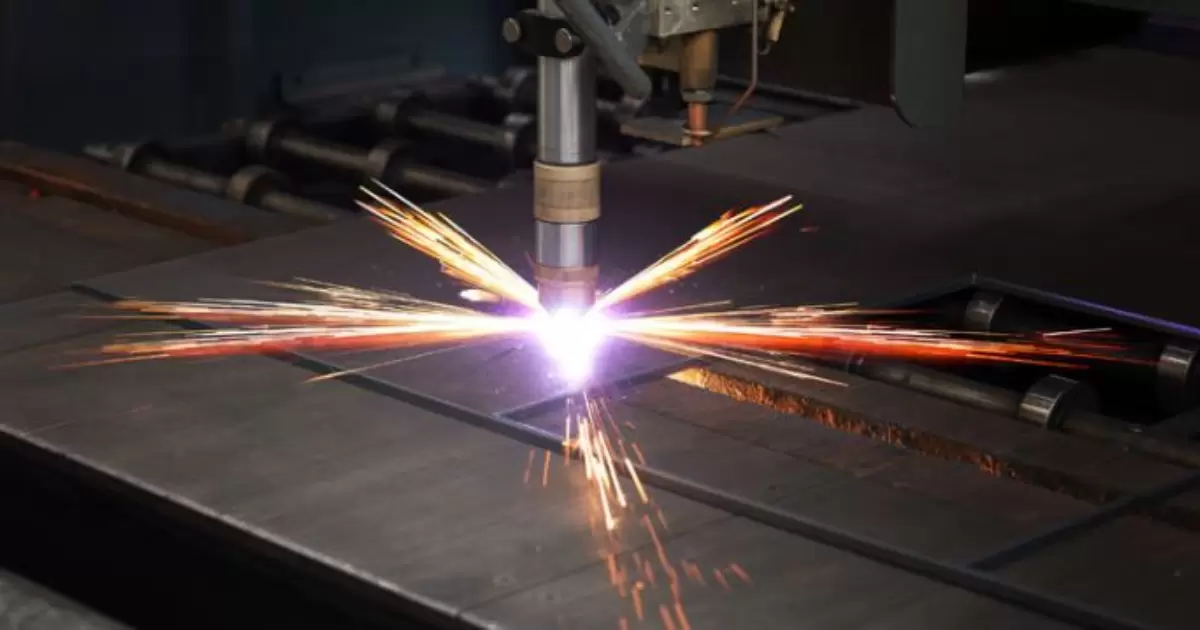

Plasma cutters paintings by passing compressed fuel through a constricted nozzle at excessive pace. An electrical arc is formed among a cathode in the nozzle and the grounded metal being cut. This turns the gas into plasma – the 4th state of count number – which can attain temperatures over 30,000°F.

The superheated plasma jet melts the metallic whilst the excessive-speed plasma stream blows away the molten fabric, ensuing in a slim, easy reduce. Plasma cutters produce very little slag and warping in comparison to other thermal reducing techniques like oxyfuel or laser slicing. They are capable of cutting metallic up to 1 inch thick.

How to Prepare Stainless Steel Surfaces for Plasma Cutting

Proper coaching of the chrome steel surface is critical before plasma cutting to prevent infection. All coatings, oils, and rust need to be removed so the surface is smooth and brilliant. Use solvents, abrasives, or descaling answers as vital. Masking the reduce line with soapstone facilitates prevent paints or inks from baking into the steel. Secure the metal with jigs or helps to decrease warmth warping during slicing.

Can Plasma Cutters Cut Stainless Steel?

Yes, plasma cutters are properly applicable for slicing all styles of stainless-steel. Their high cutting strength permits them to penetrate the long lasting surface of stainless. The plasma arc’s focused warmth minimizes distortion of the fabric around the reduce. Plasma reducing also avoids discoloration or infection of the stainless surface.

However, cutting chrome steel requires distinctive settings and strategies in comparison to moderate metal. The chromium in stainless-steel causes it to maintain warmth and conduct strength in another way. This calls for modifications to the plasma cutter’s amperage, air strain, and reducing pace. Proper coaching of the stainless floor is likewise important.

Plasma Cutter Settings for Stainless Steel

Cutting stainless-steel calls for 20-30% more amperage than slight metal. Increased energy penetrates the dense floor and heats the metal’s low conductivity edges. For reference:

– 1⁄4 inch 304 stainless steel: 45-60 amps

– 1⁄2 inch 316 stainless steel: 85-100 amps

– 3⁄4 inch 430 stainless steel: 120-150 amps

The brought warmth also requires round 10% better air pressure to maintain the arc solid and the reduce narrow. Faster reducing speeds also are encouraged to restriction warmth input and discoloration. A drag attitude of 5-15 degrees reduces mirrored image and improves reduce high-quality.

Using an appropriate torch consumables like popular or first-class reduce electrodes and nozzles additionally enhances performance in stainless. Anti-stick shields prevent molten metallic from adhering within the nozzle.

Key Facts About Plasma Cutting Stainless Steel

| Topic | Details |

| Why plasma cut? | – Fast, clean cuts<br>- Minimal heat affected zone<br>- Cuts up to 1″ thickness |

| Challenges with stainless | – Dense, low conductivity surface<br>- Requires more heat to cut |

| Amperage | 20-30% more than mild steel |

| Air Pressure | Increase by 10% from mild steel |

| Cut Speed | Slower than mild steel |

| Cut Quality Tips | – Clean/prepare surface <br>- Proper torch angle <br>- Steady cut speed <br>- Remove slag quickly |

| Thickness Capabilities | Up to 1″ stainless steel |

| Common Gases | Compressed air, Ar/H2 mixes |

Technique Tips for High Quality Cuts

Following precise techniques when plasma cutting stainless steel guarantees distortion-unfastened cuts. Hold the torch perpendicular to the paintings at a 5-15 degree drag perspective to reduce mirrored image. Maintain a consistent, even cut velocity and do no longer pause the torch over the work. Use area starts in which feasible to keep away from start craters. For interior cuts, lessen pierce settings so the hole punches thru cleanly. Slow down at corners so the reduce is correct. Remove slag right away after slicing while it’s miles still hot.

FAQs:

What metals Cannot be cut with plasma cutter?

Non-conductive materials like wood, plastic, glass, and stone can’t be cut with a plasma cutter. The plasma arc calls for conductive metal to complete the circuit.

What are the hazards of plasma cutting stainless steel?

Hazards include poisonous fumes, metal particulates, fire dangers from sparks/slag, arc eye, burns, electric shocks, and compressed gasoline risks. Proper PPE, air flow, schooling, and safety techniques are vital.

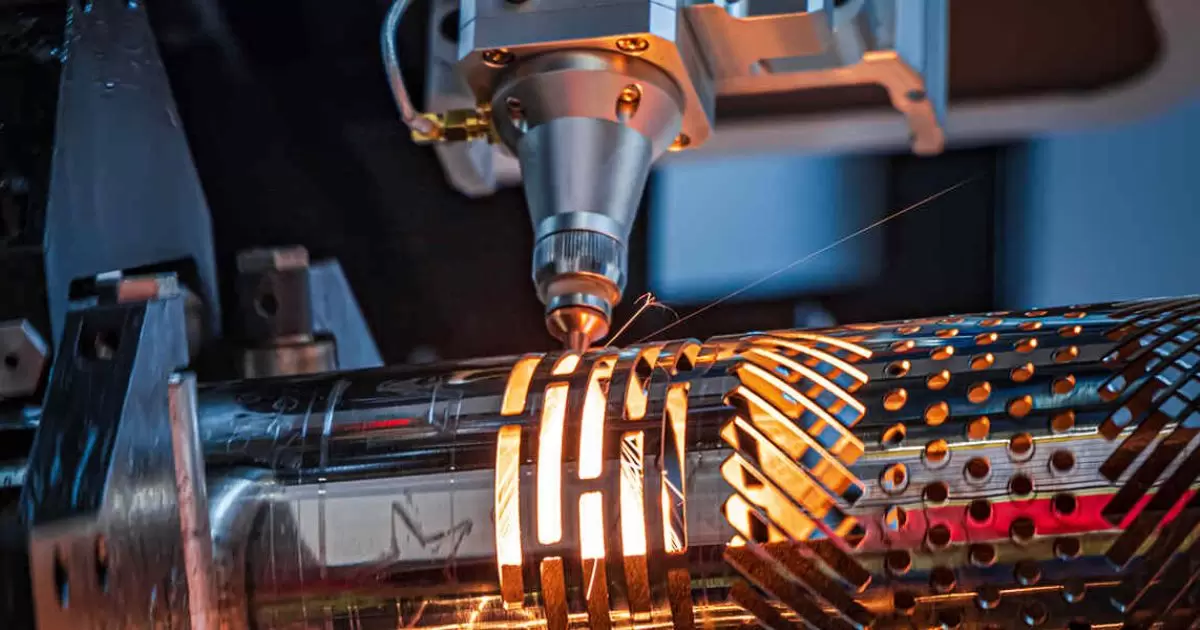

What cutting is used to cut stainless steel?

Plasma, laser, waterjet, abrasive saws, and machining equipment can all cut stainless-steel. Plasma could be very common for its pace, cut first-rate, and price-effectiveness.

What gas is best for plasma cutting stainless steel?

Compressed air is commonly used, but argon/hydrogen mixes yield cleaner cuts by reducing oxidation in some stainless alloys.

Can you plasma cut without gas?

No, plasma cutters require a gas like compressed air to generate the plasma arc. Cutting without gas will damage the torch.

Can SS material be cut with gas cutting?

Yes, oxyfuel gasoline reducing can reduce stainless-steel, however is slower and leaves more slag as compared to plasma reducing.

Conclusion:

Stainless metallic is an excellent cloth for limitless packages thanks to its electricity, durability, and corrosion resistance. However, operating with chrome steel regularly requires reducing and shaping it exactly and correctly. Plasma slicing has demonstrated to be one of the pleasant technologies for achieving easy, speedy, and accurate cuts via all types of stainless-steel.

As precise all through this text, plasma cutters are more than able to handling the dense, low conductivity floor of chrome steel. By adjusting settings for parameters like amperage, air pressure, cut velocity, and technique, operators can optimize their plasma cutters specifically for stainless-steel. Following the tips supplied here will permit you to solution the important thing query will a plasma cutter cut stainless-steel? with a definitive yes.

With the unequalled slicing strength of plasma, even rugged chrome steel up to one inch thick can be sliced through quick, cleanly, and cost efficiently. Any metallic fabrication or manufacturing regarding chrome steel have to take advantage of plasma reducing’s talents.